I finally added the additional battery bank which is 4 six volt Sonnenschein SB6 200 amp-hour under the aft cabin bunk. It fitted well and I was able to secure then with little effort. Then begun the task of rewiring Malua to divide the electronics from the motor based equipment. It was obvious that I had to isolate the chart plotter from the other components. After 18 hours of sailing with the autohelm the draw on the current fell below the chart plotters cut-off voltage and it would cut out.

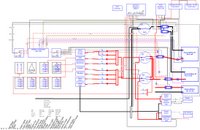

To overcome this I split the electronics on one battery bank and the motor based equipment (winches, windlass and autohelm) connected to the second battery bank. There is still the starter battery. To achieve this I had to install a second four position heavy duty switch (Off, 1, 2 both). This then had to be wired and the other wires re-routed to suit the new layout. I created the attached wiring diagram well before tackling the job. It was easy to follow and everything fell into place. I also uncover an anomaly that had challenged me since I completed the original wring. The power no goes off then the negative is switched off.

The test will come with a overnight sail with the autohelm working away but with 1,000 amp hour I am sure there is enough capacity. The gen-set will have to work hard to keep the capacity up but with a 150 amp alternator and a smart regulator it will find it easy. The two solar panel are able to put in 8 amps of current which will ensure it is always topped up.